Whisky is whiskey? Not quite. American bourbon is based on the same production principle as Scotch whisky or Irish whiskey, but small but subtle differences have developed over the years. Local conditions in particular give bourbon its unmistakable character. You can find out all about the production process below. However, the result tastes different in every distillery. If you ask the master distiller of a bourbon whiskey distillery which influences in production have the greatest impact on a good bourbon, he will tell you:

The grain, the yeast strains, the fresh white oak barrels and their storage have the greatest influence on the flavour of the bourbon whiskey!

Description of bourbon production

What is the reason for this statement, which contains nothing at all about the details of the production process, but rather ingredients? The answer to this question is as simple as it is convincing. American distilleries generally have the same production equipment and the same climate. The differentiating factor between bourbon producers is therefore on a different level.

A word about Tennessee Whiskey. For marketing reasons, Tennessee whiskey has separated itself as a southern whiskey from Kentucky Straight Bourbon and the Bourbon Act. However, apart from additional filtering using charcoal before the barrels are filled, the production process for these two types of whiskey is identical.

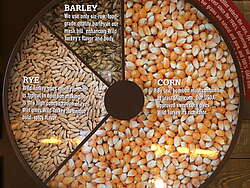

Grain selection and mixture (Mash Bill)

Each distillery has its own recipe for the grain mixture. The legal requirement for a Kentucky Straight Bourbon Whiskey is a corn content of at least 51%. However, the proportion of corn is usually significantly higher and lies between 60 and 80%. The other components of the grain blend are rye and malted barley. The latter two types of grain each make up around 10 to 15%. A few distilleries add wheat to their grain mixture (e.g. Bernheim or Maker's Mark). Wheat makes a whiskey softer and smoother on the tongue. If wheat is added, the proportion is usually around 10%.

The different types of grain are ground separately and stored temporarily. In the past, hammer mills were used as grinders until it was discovered that the grain heats up too much and the flavour suffers as a result. Today, the grain is usually crushed to open the grain husk. The subsequent grinding process produces a very fine flour.

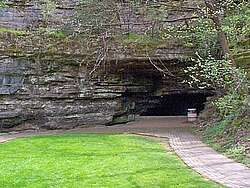

Water

Whiskey production requires fresh spring water to boil the starch in the grain and extract the resulting sugar. When the distilleries were founded and established, particular importance was therefore attached to a spring with sufficient water output. Kentucky and Tennessee lie on a large layer of limestone, which filters the water excellently. In valleys where the limestone layer is broken through, springs usually emerge, which carry wonderfully clear water that is ideal for whiskey production.

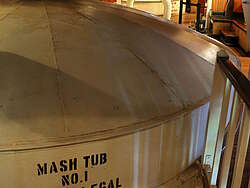

Cereal cooker (Cooker)

Cereal grains mainly contain starch. It also contains small amounts of protein, fat and trace elements. In chemical terms, starch is a poly sugar. Many sugar molecules are linked together in chains. Every type of grain germinates and can convert its starch into sugar and ultimately cellulose in this natural malting process. However, this is not always technically easy for all types of grain. Only barley has a very good ability to convert starch into sugar during germination with the help of an enzyme. For maize, rye and unmalted barley, people have therefore come up with something different. These grains are usually cooked for about half an hour.

| Sequence | Cereals | Temperature | Remark |

|---|---|---|---|

| 1. | Maize | 114°C/220°F | longest cooking time (with overpressure) |

| 2. | Rye | 77°C/170°F | medium cooking time |

| 3. | Barley | 66°C/150°F | shortest cooking time (sensitive) |

Yeast preparation

Every distillery in Kentucky and Tennessee has its own yeast strains that survived Prohibition from 1919 to 1933 in refrigerated rooms. The yeasts are so closely guarded as a secret that the companies have registered patents for their isolated yeasts. In contrast to Germany, this is possible in the United States of America.

The selection of yeast in history was done in a simple way. Containers with nutrient solution were placed under an apple or pear tree and waited until natural yeasts on the fruit accepted the nutrient solution. Small samples of the nutrient solution were then placed on carriers and the individual yeasts were incubated in temperature-controlled ovens (35 to 40°C). The entire yeast for alcoholic fermentation can then be propagated from a single yeast cell.

The amount of yeast corresponding to the tip of a pencil is taken from a test tube. This quantity of yeast is mixed with nutrient solution (malt extract) in a glass flask. The correct pH value of the solution, which must be between 5.4 and 5.8 depending on the yeast, is important when propagating the yeast.

All objects in which the yeasts are propagated must first be sterilised in an autoclave to prevent vinegar bacteria or foreign yeasts from displacing the desired yeast strain.

After around half a litre of pure yeast has been produced in this glass flask, this yeast is added to a larger container, the so-called 'dona tub'. Distilleries usually produce different bourbons with different yeasts. There is therefore a separate yeast tank for each whiskey produced.

The yeasts are therefore only propagated via the 'dona tube' from time to time if the yeast stock has been contaminated by vinegar bacteria or foreign yeasts. Distilleries generally produce different bourbons with different yeasts. There is therefore a separate yeast tank for each whiskey produced. The yeasts are therefore only propagated via the 'dona tube' from time to time if the yeast stock has been contaminated by vinegar bacteria or foreign yeasts.

Alcoholic fermentation

After the grain mixture from the cooker has cooled down to around 25 to 30°C, it can be added to a fermenter together with a large quantity of yeast, in which a beer with around 9% alcohol by volume is produced through fermentation. At this point, parts of the stillage that is later produced are also added. The stillage is part of the much-vaunted sour mash process, which is explained in detail later.

The size of the fermenters varies from 'large' to 'huge' depending on the distillery. As the continuously operating distillation columns can process large quantities of beer, a constant supply of beer must be ensured so that the distillation columns do not run empty.

The Beer Well

For this reason, American distilleries have a so-called 'beer well', into which the finished fermented fermenter contents (beer) are emptied. The beer well is usually made of stainless steel and is located in the centre of the numerous fermenters. The size of the Beer Well is determined by the size of the fermenters. As a rule, the beer well is a third larger than the largest fermenter so that the distillation columns can continue to produce even if the contents of a fermenter are pumped over late.

During alcoholic fermentation, yeasts process the sugar into alcohol and CO2. At the same time, heat is released. Fermentation usually takes three days. An alcohol content of around 8 to 9.5% vol. is achieved. A few distilleries (e.g. Labrot & Graham) ferment for significantly longer, but do not achieve higher values than 10 to 11% vol. The distiller calls the resulting product Beer or Distiller's Beer. The larger a fermentation tank becomes, the more it heats up. This is due to the fact that the ratio of surface area to volume decreases with increasing fermenter size and the fermenter can therefore no longer dissipate the heat. If the temperature in the fermenter exceeds 35 to 40°C, the yeasts gradually die off until fermentation stops. Many fermenters therefore have a water cooling system.

The result of fermentation is already assessed at distilleries such as Early Times or Four Roses. The smell of the beer says a lot about the later whiskey. The brewer attaches importance to an aromatic beer that can smell strongly of apple, for example. If the aroma of the beer begins to diminish, this indicates that the yeast is contaminated and a new yeast strain is used for the next batch. After alcoholic fermentation, the beer is distilled into raw whiskey, the white dog.

Firing process

With one exception, all American whiskey distilleries (with the exception of Labrot & Graham) use a column still (distillation column) for the distillation process. The column still allows continuous distillation and was invented by Robert Stein (Haig) in Scotland in 1826. The basic operating principle is simple: a vertical pipe is erected with a height of 5 to 20 metres and a diameter of 70 to 150 cm. Perforated bottoms are inserted into this pipe to create a connection from the bottom to the very top. The edges of the holes are bent up slightly so that any liquids cannot run straight through to the bottom. In addition, small tubes are inserted so that any liquid that collects on the trays can drain to the next lower tray.

If the column is now filled with beer at the centre position and the column is heated from below, two opposing flows are created. The liquid beer flows downwards through the tubes, while the gaseous components (alcohol vapours) flow upwards through the holes. The temperature of the column is set so that alcohol is gaseous at the top (78 - 85°C) and the beer boils at the bottom (95 - 100°C).

This process continues indefinitely as long as sufficient beer is added to the column. While the alcohol is removed at the top, the water with the fibres and remains of the grains accumulates at the bottom of the column. This product is called 'stillage' and is processed into animal feed and added back to the fermentation process as sour mash. Small distillation columns deliver an alcohol content at the top of around 120 American proof (60% alcohol by volume). If the columns are higher, the alcohol content can be increased even further. Up to 80% vol and more.

After the alcohol is removed from the distillation column, the vapour is passed through the doubler, a copper container. A catalytic conversion takes place in it, which improves the flavour of the whiskey. This doubler is required in many distillation columns because the systems or column trays are not made of copper. In copper pot stills, as in Scotland, a constant catalytic conversion takes place during distillation. In column stills without copper components, extra contact between the distillate and copper must be ensured. These doublers were developed for this purpose.

The alcohol vapour, which is liquefied again in the condenser, is fed via an alcohol vault into collecting tanks, from which either the barrels are filled or lorries are loaded for transport. The White Dog is regularly tasted immediately after production, for which it is diluted to around 20% alcohol by volume. Around 5 US gallons of 100 proof spirit are produced per bushel of grain (35.24 litres) (9.5 litres of pure alcohol). If you convert this with the weight of the grain, you get about 400-450 litres of pure alcohol from one tonne of grain.

Sour Mash

Today, all American distilleries use the sour mash process. Sour mash means that part of the distillation residue (stillage) is added back to the mash. After the mash has been prepared with fresh spring water, it is chemically neutral. This means that the chemical environment is neither acidic nor alkaline.

In chemical terms, this property is measured by the pH value. A neutral solution has a pH value of 7. The pH value of an acid is less than 7. Strong acids have a pH value of 3 to 4. If the pH value is greater than 7, it is referred to as an alkali (base). Strong alkalis have a pH value of 10 to 11.

After the addition of neutral water, the mash has a pH value of around 7 (neutral), in which the yeasts cannot work optimally. The addition of part of the very acidic stillage (pH 5.0 - 5.4) leads to an acidification of the entire mash. The pH value after the addition of the stillage is around 5.4 to 5.8. Acidic enough for the yeasts to do their work optimally. Some bourbon producers try to give their product a special addition with the term 'sour mash'. Other sources speak of a disinfecting effect of the sour mash process on the mash. The sole purpose of sour mash is to set a pH value that is favourable for the yeasts. The rest of the sour mash story belongs in the realm of marketing.

Animal feed

The so-called setback accumulates at the bottom of the distillation column. It consists of water, protein, fat and the fibres of the mash, while the more volatile substances such as alcohol and esters are removed via the top of the distillation column. This aqueous solution at the bottom of the distillation column is pumped out of the tank below the distillation column from time to time. First, the fibre portion of the still is collected through sieves. The remaining liquid portion is dried in large drums using superheated steam. The solid components that adhere to the drum wall are then mechanically stripped off and sold to farmers as animal feed. The cattle feed is very high in protein and fat and also contains a large amount of trace elements.

Filling into barrels

In Kentucky and Missouri, companies have specialised in the production of barrels made from American white oak. The barrels may only be used once for straight bourbon whiskey. They have a capacity of around 53 American gallons (approx. 200 litres). The term barrel is often used in the American context. There are various definitions of a barrel. The most famous barrel is the petroleum barrel with a volume of 158.97 litres. However, the normal American barrel contains 31 ½ gallons = 119.23 litres. 1 gallon corresponds to 3.785 litres.

The staves of the barrels are first joined together and not yet fully closed. The staves are then softened with hot steam so that they can be bent into their oval shape.

But now there is a special feature that gives the Kentucky Straight Bourbon its special flavour. The barrels are held over a light fire with one side still open. This process is called toasting and causes the wood sugar in the staves to caramelise on the inside to a boundary layer. This reddish layer is also clearly visible later when the cask is disassembled. The toasting process takes about 12 minutes. After the toasting process, the barrel is subjected to a much stronger fire treatment. It is burnt out from the inside with a large flame for 6 to 12 seconds. This gives the barrel a layer of charcoal on the inside. When producing barrels, the thickness of the charcoal layer is specified (grade 1 - 4).

After filling, the barrel is sealed with a 'bung' and transported to the warehouses by lorry.

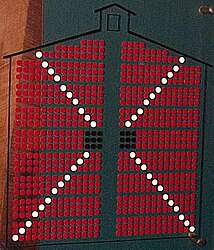

Barrel storage

Each distillery has found its own arguments and preferences for the different ways of storing the barrels. In the past, warehouses were built that were 4 to 5 storeys high. Between 3 and 6 layers of barrels are stored on each floor.

Bearing with rotation

For this purpose, the warehouses have a skeleton of beams and girders that allow the barrels to be rolled horizontally. Between this skeleton there are lifts that allow the barrels to move vertically. A standard warehouse has a capacity of around 20,000 barrels.

A very special climate is created in these warehouses. Very high temperatures prevail under the roof in summer, whereas it remains as cool on the ground as in an air-conditioned room. To equalise the temperature with the ambient air, a warehouse has many windows that can be opened as required.

The whiskey matures very differently on the different floors. In the past, the barrels were therefore usually rotated. When rotating the barrels, the barrels are moved through the warehouse in predetermined, different positions during storage so that each barrel can benefit from the good positions in the centre of the warehouse. However, a certain part of the warehouse must remain empty for rotation. As a rule, this is 1/3 of the capacity. Maker's Mark was one of the few distilleries that still rotated its barrels in 1999.

Storage without rotation

Other distilleries have taken a different approach. They deliberately no longer rotate, but mix barrels from different positions in the warehouse before bottling. This approach avoids the labour-intensive rotation of barrels, utilises the warehouses in their entirety and creates a region in the centre of the warehouse where you can find excellently matured barrels for small batch bourbons and single barrel bottling.

Warehouse fire

In 1996, several warehouses at the Heaven Hill distillery burned down. The burning whiskey made its way through the distillery down to the river. As a result, the distillery also fell victim to the flames and the whiskey continued to burn on the river all night.

Today, attempts are made to avoid the risk of fire by ensuring that each warehouse has a sprinkler system and that the warehouses are built at a safe distance from each other. As a passive safety measure, the wooden skeleton is designed so that the warehouse collapses in the event of a fire and does not damage other warehouses.

Bottling

Bourbon distilleries have such a large output that all distilleries can afford their own bottling plant. Even distilleries as small as Maker's Mark and Labrot & Graham have their own facilities. First, the selected barrels are lorried to the bottling plant and emptied through sieves. The pieces of charcoal that have become detached from the barrel wall during storage are retained by the sieve. The bourbon is pumped into a storage tank, from where it is fed into a bottling line.

American whiskey is bottled in a wide variety of bottle sizes, shapes and materials. Typical sizes are 0.2 litres (flat bottle), 0.7 litres (Europe), 0.75 litres (US market, Japan), 1.0 litres (travel value), 1.89 litres (1/2 gallon). The bottles are increasingly being made of plastic (PET) for mass-produced products.

To comment, you must be logged in