Wood as a raw material!

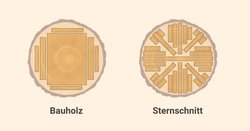

A wooden cask is a small work of craftsmanship. Although more and more machines are being used to make barrels these days, the actual manufacturing process is still carried out by people. The boards for the staves, i.e. the bent oak planks, cannot simply be cut at right angles from a log like timber. Attention must be paid to the direction of the wood's fibres so that none of the wood's radial vessels penetrate the barrel wall. In the latter case, too much alcohol will evaporate or the barrel may even start to leak. Only oak wood is suitable for barrel production. Softwood species contain resin, for example, which prevents the barrel from breathing. Other types of wood give off unpleasant flavours that make the whisky unusual or even undrinkable. Oak wood from trunks between 70 and 200 years old is ideally suited.

American Oak

The wood for the barrels is mostly American white oak from the central to eastern part of the United States and parts of eastern Canada. The raw material comes directly from the country's sawmills. A freshly cut tree has a moisture content of about 50 %. This is far too much for the production of barrels. The sawn timber (boards) is dried in several steps to a residual moisture content of 12 %. Some of the boards are matured for several months to change the flavour of the wood. The seasoned wood contains much less tannins. These are responsible for the bitterness. Bourbon is very sweet and not bitter at all, so the staves must rest in the air for at least six months.

The next requirement is the quarter cut. This cut ensures that the alignment of the annual rings is in the right direction and that the barrel has sufficient stability and tightness. This cut also divides the boards into wide and narrow pieces.

The boards are then cut into short and long pieces. The short pieces become bottoms and the long pieces become staves, which are used to make the camber of the barrel.

Production Management

First, the surfaces of the wood are planed. This brings back the light colour of the wood and also makes the barrel more resistant to external influences. Then a machine drills holes in the sides of the planks and inserts wooden dowels on one side. Now you have wide and narrow pieces of wood that can be joined together.

The next step is to dowel these planks into a square of flat oak. This square is cut into a perfect circle with a rounded edge. This is the raw end of the barrel.

The heads then go into the oven and are charred under an open flame for about 90 seconds. You can read more about charring a barrel later in this article. The final step for the lids is to dip the rims in paraffin wax. The wax ensures the air-tightness between the lid and the body of the barrel. Finally, the lids are stacked and transported to the next department.

The Staves

The long staves are also planed to improve the colour and resistance to external forces. Now they are milled into a very complex shape. The cross-section of the finished stave is trapezoidal because the inner circumference of the barrel is smaller than the outer circumference. The stave is narrower at the top and bottom than in the middle because the barrel is wider in the middle than at the ends. The expert calls this a convex curve.

The Keg Tapping

This is the heart of barrel making. Each barrel maker inserts 31 to 33 wide and narrow staves into a temporary steel ring that holds the staves together. He or she must make sure that the wide and narrow staves are evenly distributed on the circle, otherwise the forces holding the barrel together will also be uneven. In this case, it is likely that the areas with less pressure will leak.

The Steaming

If the barrel were simply bent into shape, the staves would break and the barrel would be lost. Therefore, the lifted barrels are turned upside down with the wide end facing down. Then hot steam is blown through the staves to make them flexible.

A worker can then put on the second temporary steel ring. This is the first time the barrel has its final shape. Two more thick steel rings are added and now it goes into the heat treatment.

The Toasting

In front of the ring fixation picture you see the inside of a raw barrel. It is just as light as the outside of the barrel. The barrels go into a roasting area where the inside of the barrel is heated to a certain temperature. The exact temperature, time and process are a secret, as this is one of the most important factors in making a good bourbon or Tennessee whiskey.

The wood is sugared to provide nutrients to the various parts of the tree. The best way to experience this is to harvest maple syrup. Oak has a lower sugar content, but also contains a substance called tylose. This ensures that the barrel is waterproof. The oak is the perfect combination of tyloses and sugar. By heating the barrel from the inside, the sugar liquefies and expands greatly. This forces the sugar to come to the surface and turn into caramel as well. These tasty caramel compounds are easily dissolved by the raw whiskey (alcohol) and thus contribute to the flavour profile of the whiskey. The caramel is also the reason that the matured whiskey gets its brownish colour. This is called additive maturation because it adds flavour to the whiskey.

This toasting process is not necessary for the production of a bourbon or Tennessee whiskey. Although most bourbons are known for their sweet and caramelly flavour profile, in most cases the barrels are toasted. In the next picture you can see that the inside of the barrel is now dark brown. They have been toasted.

Charring of the Casks

When the barrels are charred, they are burnt from the inside with an open flame. This is done much hotter and for a shorter time than toasting. And while toasting penetrates deep into the wood, charring only burns the top layer of the wood.

This charcoal layer acts as a filter. The charcoal reacts with the pungent substances of the white dog (raw whiskey). The pungent and undesirable flavours are removed from the whiskey. Experts call this subtractive maturation because it removes unwanted flavours. The laws for Bourbon and Tennessee Whiskey prescribe a charred barrel for maturation. However, there are different types of charring. The intensity of charring is counted from one to four, with four being the highest. The number four is often called alligator charcoal because the surface of the burnt wood breaks up and looks like the rough skin of an alligator. The charcoal is the reason for the smoothness of bourbon and Tennessee whiskey. However, Tennessee whiskey has another trick up its sleeve.

Intensity of Charring

Toasting and burning out the inside of the cask wall during cask making caramelises the wood sugar and gives the whisky vanilla and caramel notes. At the same time, the charcoal layer acts as a filter that removes sharp substances from the whisky, making it softer. The strength of the burnout therefore determines the influence the charcoal layer will have on the aroma of the whisky. In the bourbon industry, there are generally four different degrees of burnout. For 'No. 1 Char' the flame is held in the cask for 15 seconds, for No. 2 for 30 seconds and for No.3 for 35 seconds. The highest degree, No.4 lasts for 55 seconds and leaves regular charcoal plates on the inside of the barrel staves. Due to the scaly appearance of the barrel wall, the highest degree also received the name 'Alligator Char', because it resembles the armoured skin of an alligator.

Toasting and burning out a cask takes place during its production and has the greatest effect in the first years of ageing. If a cask is reused several times, the effect on flavour decreases. A fresh cask has a relatively long life of several decades and is relatively expensive. For this reason, barrels today are often reprocessed, i.e. scraped out and burnt out again. Such barrels are called rejouvenated. In this way, the casks release more aromas into the whisky. However, this is only possible as long as the cask wall retains sufficient strength to support the weight of the contents. The modern storage of the casks standing on pallets makes these thinner walls possible.

The Hoops

The stirrups are formed in the iron department. They are cut from steel coils into three different lengths. These form the three different types of hoops that a barrel has. The first is the head hoop at the ends of the barrel. The quarter tyres are the next on the inside, and then there are the two bilge tyres. They are the furthest inside.

All the tyres are riveted together. During the riveting process, the cooperage presses its signature into the rivets. So if you see a barrel with BB on the rivets, you know it is from Brown-Forman Barrel. The barrels with MO on the rivets come from another company in Missouri.

The Hooper

Before you can continue with the production, you have to cool down the barrel. During cooling, the barrel shrinks. If you were to put the tyres on before cooling it down, the barrel would shrink and the tyres would fall off, causing the barrel to collapse. After cooling, the trenches for the lids are cut along the circumference and the prepared lids are connected to the rest of the barrel. Finally, the temporary tyres are replaced by the real head tyres, followed by the other tyres. They are pressed down by a machine called a hooper.

The Bunghole

The bunghole is the entrance and exit for the whiskey. It is located on the side of the barrel exactly in the middle between the bottoms. The bunghole must be placed directly in the middle of a wide stave. This minimises the risk of the stave breaking at the hole and leaking at the line between two staves near the hole. At Brown-Forman, a laser is used to mark the location where the bunghole is drilled.

Immediately after drilling, a gallon (3.7 litres) of water is poured into the barrel. It is then turned so that the water touches all the staves and the barrel gets really wet inside. Now air pressure is added and you can see if there are any leaks. If there is a leak, you will see water bubbles forming at the leaky spot. It is important that the barrel stays moist. If the cask dries out, the wood will shrink and the stability and tightness of the cask will be in danger. That is why most distilleries keep some water or whiskey in their empty barrels. Finally, a temporary plastic plug is attached and the cask is delivered to the distilleries for the maturation of the whiskey.

Tasks of the Cooper Station

The place where casks are reconditioned is called 'cooperage'. The coopers or cooperage have numerous tasks related to the casks. Here, casks are not only manufactured, but also reconditioned and various repairs are also carried out.

If a cask fails the air-tightness test, it goes to the cooperage. Here, the most experienced workers at the factory repair the broken barrels. The bottoms are replaced as a whole or the trenches are cut a little deeper. If a stave is cracked, the individual stave is replaced. Small leaks are repaired and the barrel is returned to the original inspection station.

Reuse of Casks

Cask costs account for a not inconsiderable proportion of the cost of producing whisky. The cask accounts for about 10 to 20% of the production costs. The increased demand for casks in the whisky industry has also pushed up cask prices. So, Scotch-wise, it makes sense to use casks more than once. Whisky can be matured in casks about three to four times, by which time most of the aromatic substances have been extracted from the wood.

The first fill of the cask (1st fill) is therefore particularly interesting. This does not mean the original filling of the cask with bourbon, sherry or port, but the first Scotch Malt Whisky that is filled into a cask. This 1st fill extracts the strongest aromas from the wood.

Let's remember: heating, toasting, activates the wood. The hallmark of this is the Red Layer, which separates the active from the inactive wood. Who is stopping us from scraping out the inside of the barrel several millimetres and toasting it again? After toasting, you freshly burn out the barrel and voila, we have a new, active barrel.

A bourbon cask, used for two to four years in the US, can serve for another 30 years in Scotland. After the above-described reprocessing, which the experts call rejuvenation, the cask can again serve for 30 to 40 years. And then the barrel can be revived once again. How old barrels can become has not yet been tested. Barrels have only been reconditioned for a few decades. But not everything on the barrel is reconditioned. Most of the time, the barrel is given new discs (ends) because the old ones do not survive the reprocessing.

Remanufacturing is the future. With little effort, the life of the barrels can be extended considerably. It is not only the money saved that counts. It is above all the taste characteristics that make a reconditioned cask so popular in the whisky industry.